On top – futuristic ski mountain

The enormous roof of the state-of-the-art waste-to-energy incinerator Amager Resource Centre in Copenhagen provides valuable space for leisure and recreational activities. © Ehrhorn Hummerston

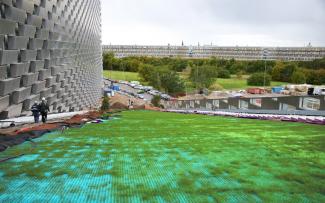

Copenhill has skiing pistes, hiking paths and trails in a wild natural landscape and the highest climbing wall at just under 90 m. © Ehrhorn Hummerston

The building stretches over 22 storeys to a height of almost 90 metres, offering a magnificent view of Copenhagen and towards the sea. © Ehrhorn Hummerston

The people of Copenhagen can now ski the whole year round on their doorstep - without a long journey and, above all, more environmentally friendly than with the energy-intensive indoor skiing. © Ehrhorn Hummerston

Grass growing through the synthetic mats on the skiing slope. © Malmos A/S / ZinCo

The considerable plant diversity is a valuable habitat for birds, bees, butterflies and insects. © SLA

Daisies provide for a wonderful meadow character among the plants. © Malmos A/S / ZinCo

Wild nature just like a real mountain – with a lot of pine trees. © SLA

Skiing on synthetic mats actually feels a bit like skiing on hard snow. © Ehrhorn Hummerston

The vision of the Bjarke Ingels architects became a wonderful reality. © BIG

With its futuristic Amager Resource Centre, Copenhagen has actually acquired a green landmark. © BIG

Any kind of build-up can be anchored in the concrete foundation – for example these original and almost never-ending wooden benches. © Malmos A/S / ZinCo

The drainage elements Protectodrain® PD 250 are installed around the concreted abutments, beside the hilly mountain pathways. © Malmos A/S / ZinCo

The ZinCo system substrate was hoisted onto the roof using a crane and distributed from the big bags. © Malmos A/S / ZinCo

The vegetation mats are used in particularly steep areas. © Malmos A/S / ZinCo

The grass growing through gives the finished ski slope a very natural look. © Malmos A/S / ZinCo

Amager Resource Centre Copenhagen, Denmark

In Copenhagen, an audacious vision for the design of a waste-to-energy plant has become a reality in a highly impressive manner. Since opening at the start of October 2019, the impressive Amager Resource Centre, with its approx. 16,000 m² of roof area, has provided any amount of skiing fun with its four ski lifts. It has various trails for hikers and steps for those who want to walk up the Amager Bakke (mountain) or Copenhill, as the 87 m high “new local mountain” is called. The ZinCo building protection and drainage elements Elastodrain® and Protectodrain® provide a secure base to allow the roof to be used in this unique way and for anything else that will be growing there – from the smallest blade of grass to the tallest tree.

Copenhagen, the capital of Denmark and an important city in Northern Europe, is considered to be one of the cities with the best quality of life in the world. The metropolitan area of Copenhagen covers a number of islands, including the northern part of the 96 km² island of Amager which is situated in Oeresund, the strait that divides Denmark and Sweden. In urban planning terms, the focus here is on renaturing and new recreational and residential areas. A location had to be found near the city centre for the new incineration plant in Copenhagen that would supply about 100,000 households with electricity and heat. But, who would want a plant like this in their backyard? Copenhagen has managed to create a green and unusual land mark with this contemporary Copenhill.

A remarkable vision

The visionary architects in the Bjarke Ingels Group imagined the Amager Resource Centre as a functioning recreational facility. Their guiding principle is sustainability that is fun for everyone. Therefore, they bravely turned the taboo that is the incineration plant into something positive. The plant is not a disagreeable and isolated building but is placed directly into the social context. The chosen location is the former North Harbour of Amager with its industrial past, which is already the scene for many sporting activities such as water skiing, sailing, go-karting and free climbing. In view of the planned height of the building at almost 90 metres, the idea of a ski slope stretching across the 60 m wide and 200 m long building wasn’t long in coming. The 450 m of piste, ranging from steep to flat, can now be used all year round for beginners and experts, on skis or snowboards. Dry slopes, which are slopes made of synthetic materials, already exist in some places, but a dry slope on a rooftop is unique worldwide.

A joint effort

This fantastic vision of the architects was planned and implemented step by step over the past nine years. The demanding challenges posed by this unprecedented, multi-functional facility were successfully met thanks to the close collaboration of everyone involved in the project right from the start. As regards the roof design, this involved above all the architects and nature designers from SLA, the garden and landscape company Malmos A/S and the green roof specialists, ZinCo, whose engineers also found themselves in uncharted waters with this project. And their motto “Anything is possible on a roof” was true to form.

Safe from wind and weather

One fundamental issue with a roof that has a pitch of up to 30° is the matter of stability or protection against erosion, given that both severe rain events and sea wind are key factors with a building of this height. The concrete roof with an area of up to 16,000 m² and a bitumen seal, has, for this reason, diagonal barriers that are also sealed and that guide the water coming off the slope towards the roof outlets at each side. In addition, numerous abutments were concreted on top using screw anchors, particularly in the area where trees were later to be planted. Depending on the required use in the individual areas, ZinCo anti-slip drainage sheets Elastodrain® and Protectodrain® were installed over this foundation.

On mountain paths

There are steps on each side of the slope with varying tread depths and a meandering network of pathways for hikers, covering an area of about 3,000 m². This is where the extremely durable drainage and building protection Elastodrain® EL 200 made of fully vulcanised rubber was installed. This was followed by the system filter PV and galvanised reinforcement mesh on the corresponding spacers, which were then set centrally into the concrete. The concrete was maintained as a visible surface, in very hilly form, to simulate a mountain pathway for the hikers.

Green mountain

An area of 3,000 m² was planted on the “mountain” as a robust natural landscape. The highly durable ZinCo drainage boards Protectodrain® PD 250 made of ABS plastic are used here and they are also anti-slip due to the rubber protection mat attached to the underside. The system filter was followed by 5000 t of ZinCo system substrate made of recycled clay tiles. Some of it was blown onto the roof and partly distributed by conveyor belt or hoisted onto the roof in big bags using a crane. The substrate depth ranges from 20 cm to 100 cm in the areas with shrubs and large root balls. Plant types that are typical for Denmark were chosen - robust enough to thrive in the special micro climate on the roof. In very steep areas that are therefore at risk of erosion, vegetation mats are installed that have been specially pre-cultivated for more than a year. This is the case just beneath the trees which require a particular anchor. An upstand grid was laid over the concreted abutments, thereby creating stable fixing options for tying down the root balls.

Planting the 300 trees and ensuring that they are protected from wind and erosion was particularly challenging when you consider that the largest tree weighs 2.5 t. Naturally enough, these works required calm weather.

Drip-line irrigation ensures that the green mountain will permanently thrive. In this way, this species-rich vegetation with its grasses, herbs, perennials, shrubs and trees can and should serve as a “green cradle” for seeding the surrounding area of Copenhill.

Preparing the ski slope

Once it was prepared, the artificial ski slope did what it promised to do. The only requirement is that the grass that is growing through is mowed regularly so that the downhill skiers won’t be slowed down. This is why the drainage elements Protectodrain® PD 250 with system filter have also been installed over an area of 8000 m². The next layer, the substrate, is sandwiched between two synthetic nets that are attached to each other with about half a million cable ties. About 70,000 metal plates are also integrated into this layer package to which the actual piste surface consisting of 30 × 30 cm synthetic mats from the Italian manufacturer Neveplast is attached using screws. The five different mat shades from light green to dark green and the different gradients make the piste look like a natural slope on which real grass is growing. The button lifts are also absolutely genuine as are the three conveyor belts as climbing aids. Alternatively, there is a lift that brings all recreation enthusiasts and visitors directly to the viewing platform and café at a height of almost 90 metres. From there, you have a view not only of Amager Bakke but of all Copenhagen and Öresund, all the way to Malmö.

Groundbreaking around the world

The waste-to-energy incinerator Amager Resource Centre is a project that combines technology, ecology and sport in a futuristic way. It looks like a mountain. Inside, the latest and most environmentally friendly generation of power plant, outside the façade made of aluminium cassettes which even has a climbing wall, and at the top a diverse natural landscape for all types of sporting activities.

Visitors can take a look at the modern workings of the plant during a guided tour – a nudge to think about the topic of waste and one’s own consumer habits. The plant processes the waste from about 550,000 inhabitants and 45,000 companies and supplies the city with recycled materials, electricity and district heating. Generating energy from waste and therefore not relying on fossil fuels is contributing to reaching climate targets. By 2025, Copenhagen wants to be the first climate-neutral city in the world.

The ambitious goal of integrating a waste-to-energy incinerator into the city and giving it true added value has been an outstanding success and it fills all those involved with great pride and joy.

“Anything is possible on a roof” – in line with this motto, a green urban space has been created in Copenhagen that is a role model for the future.

Author: Heidrun Eckert, ZinCo GmbH

Site board

Construction project / Developer: Amager Resource Center, 2300 Copenhagen, Denmark

Construction year: 2018/2019

Roof area: approx. 16,000 m²

Green roof build-up: ZinCo green roof tailored solution with Elastodrain® EL 200 / Protectodrain® PD 250

Architect: BIG Bjarke Ingels Group, 2500 Copenhagen, Denmark

Landscape architect: SLA, 2300 Copenhagen, Denmark

Green roof contractor: Malmos A/S, 4000 Roskilde, Denmark

System supplier: ZinCo Danmark A/S, 4000 Roskilde, Denmark

System manufacturer: ZinCo GmbH, 72622 Nuertingen, Germany

Engineers: MOE and Rambøll

Collaborators: Copenhill A/S, Jesper Kongshaug, BIG Ideas, AKT, Topotek 1, Luechinger + Mayer, Man Made Land, Realities: United

Thanks to: A.P. Møller Fonden, Lokale og Anlægsfonden, Nordea Fonden, Fonden R98, Københavns Kommune, Frederiksberg Kommune, Tårnby Kommune, Dragør Kommune og Hvidovre Kommune

For further information, please contact:

ZinCo Green Roof Systems Ltd.

F26, Elmfield House, New Yatt Road

Witney

OX28 1PB

Telephone: +44 1993 229700

e-mail: office@zinco-greenroof.co.uk